UCSF Medical Center at Mission Bay Incorporates Best Practices in Seismic Safety

A special hard drill machine was brought in to penetrate a particularly dense layer of rock. Image courtesy of DPR Construction

Exactly 22 years after a 6.9 earthquake caused widespread structural damage in the San Francisco Bay Area, members of the UCSF community gathered on a picture-perfect morning to celebrate a construction milestone at an emerging medical center that incorporates the best practices in seismic safety.

It seems fitting in a way that 22 years ago today was the Loma Prieta earthquake, and today we’re building a new building that will withstand anything that Mother Nature wants to put in our way,” UCSF Medical Center CEO Mark Laret told the crowd at the Oct. 17 “Topping Out” ceremony at Mission Bay, which marked the end of the $1.5 billion project’s structural steel phase. “This will be spectacular.”

Planners and architects behind the UCSF Medical Center at Mission Bay are making sure the 289-bed facility will seamlessly accommodate its existing patients, as well as new ones, in the event of an emergency.

“Hospitals are designed above and beyond all other buildings” when it comes to safety, said project architect Herb Moussa of the San Francisco-based firm Anshen + Allen, part of Stantec Architecture. “They cannot collapse and nothing critical can be damaged in a major earthquake or other disaster. UCSF’s project has an additional goal: to remain totally operational.”

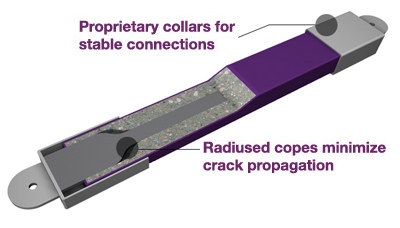

To accomplish that, the 878,000-gross-square-foot facility, which includes specialty hospitals for children, women and cancer patients, is being bolstered by more than 330 buckling restrained braces to protect it against earthquake-related stresses or extremely high winds, Moussa said.

Each brace is composed of a steel plate core shaped like a small rectangle that is surrounded by a tube filled with grout. If the building shakes, Moussa said, the core stretches and compresses, while the grout keeps it from buckling.

“Buckling restrained braces aren’t entirely new, but they are the best proven state-of-the-art braces out there,” he said.

In addition, due to the specific geotechnical conditions of the medical center site – including a compressible clay known as Mission Bay mud – the project team chose an auger cast pile foundation system, which requires workers to drill about 60 to 70 feet into the ground using a hollow drill bit that is then pumped full of grout and reinforced with a central steel bar and surrounding steel reinforcing cage.

“The foundation system is unique to the zone the project is located in, as well as the site conditions,” Moussa said. “This is a good, cost-effective system for the kind of earth that’s below us at Mission Bay.”

Seismic safety was a major consideration from the very beginning of the planning process, said Stuart Eckblad, the project’s director of design and construction.

“Really early on, you have to make decisions about how to structure the building —whether to use a braced frame or a moment-resisting frame — and what type of foundation to use,” he said. “We made our decisions based on what was most ideal for our soil conditions and the way the individual buildings are laid out, as well as economics. And we still have a reasonable amount of flexibility if we want to renovate later.”

The new hospital complex will be reinforced by more than 330 Star Seismic "PowerCat" buckling restrained braces capable of stretching and compressing during an earthquake or extremely high winds. Image courtesy of Star Seismic

To leave nothing to chance, before moving forward with construction, project engineers tested two very large mockups of the hospital’s exterior wall, using hydraulic rams designed to simulate a major quake.

The result of these precautionary measures: A building that can survive and remain operational after at least an 8.0 temblor from the San Andreas Fault, Moussa said.

“People are curious about how often we expect an 8.0 earthquake happening along San Andreas. It’s about once every 2,475 years,” he said. “And there’s about a 2 percent chance of an earthquake exceeding that (magnitude) in the next 50 years.”

Plans for the Mission Bay hospital complex stemmed in part from the University’s need to address seismic safety issues at two of its oldest patient care facilities: UCSF Medical Center’s hospital at Mount Zion and Moffitt Hospital at Parnassus Heights.

California law requires hospitals to retrofit or replace buildings that fail to meet the state’s rigorous seismic safety standards by 2013, or later with an approved extension. Mount Zion has until 2015 to undergo retrofitting or cease inpatient operations. UCSF Medical Center has until 2030 to replace Moffitt.

These stringent seismic regulations have contributed to a steep increase in hospital construction costs statewide, which nearly doubled between 2001 and 2007, rising at a rate of 14 percent per year above the Consumer Price Index, according to a report by the California HealthCare Foundation.

On Nov. 29, the Federal Emergency Management Agency (FEMA) approved a $3 million grant for the seismic retrofit of two Mount Zion buildings, both built in 1948, to bring them into compliance with current state regulations.

The need for state-of-the-art, seismically sound medical facilities lasts far beyond the hours and days immediately following an earthquake or other disaster, experts say. And the positive effect they can have extends to the non-patient population as well.

“Hospitals are a beacon of life and hope for a community,” the California Office of Statewide Health Planning and Development wrote in a March 2010 Hospital Seismic Safety Bulletin. “If these buildings are damaged so that they cannot function, society remains vulnerable. Without functioning hospitals, it takes much longer for a community to recover from a disaster.”

To install the auger cast pile foundation system beneath the Mission Bay medical center, workers drilled 60-70 feet into the ground using a hollow drill bit that was then pumped full of grout and reinforced with steel. Image courtesy of DPR Construction